Glissando

Overview

The Glissando is Peco InspX’s high performance glass-in-glass X-ray inspection system.

The Glissando offers extremely high performance inspection by including an inspection through the bottom of the glass container as the package is conveyed on an X-ray optimized conveyor belt (requires package transfer).

Multiple X-ray tubes create high amplification of foreign material on the bottom of the container.

Height adjustable X-ray beams allow inspection of a wide range of glass container formats from small baby food jars to very large gallon pickle jars.

Customers are encouraged to consult with a Peco InspX sales specialist to determine which inspection machine is best suited for their glass application.

Features

Modular Design

Fill Level Measurement

Conveyor Drive

Real-Time Remote Support

Robust IT Security

Advanced X-ray Tube/Detector Design

No Requirement for Container Spacing

Large Container Glissando

Typical Applications

Glass Food Containers

Glass Beverage Containers

Enhanced Metal Can Inspection

What Makes Peco Inspx X-ray Systems Different?

High Speed Operations

Service

Software

Made in America

Tech Specs

Technical Information

Architecture

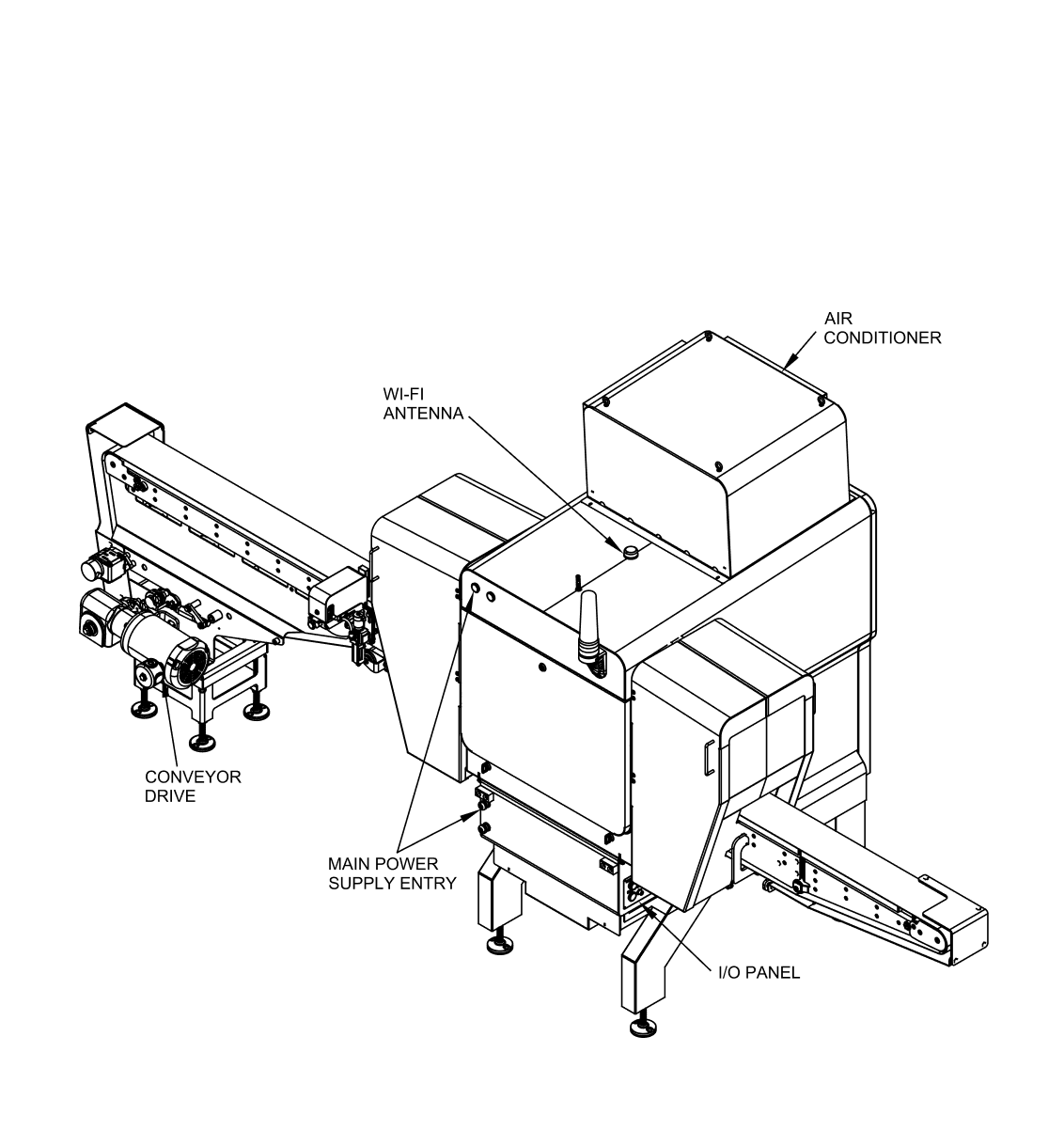

Conveyor

X-ray Tube Configuration

Aperture Size

Environment

Line Speed

Input Voltage

Air Supply

Ambient Temperature

Diode Size

Container Ejection

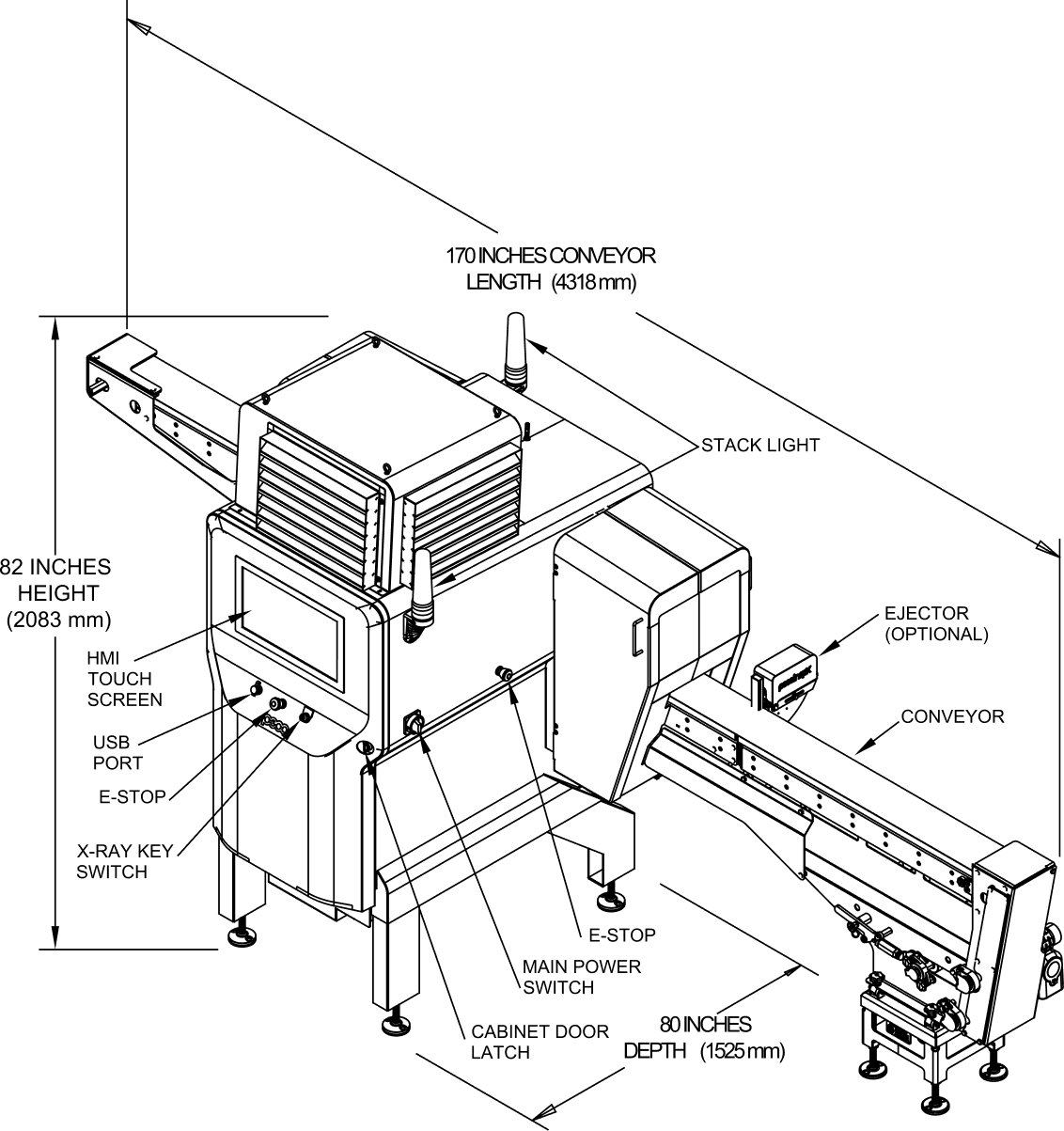

Dimensions (LxDxH)

Safety Rating

Computer

Connectivity

Supported SCADA Systems

Supported Cloud Platforms

Operator Interface

Construction

Technical Information

Options

Industrial IoT Capabilities

Peco InspX offers industry leading plant connectivity and remote control including:

- SCADA integration via OPC-UA protocol into Ignition, Wonderware, FactoryTalk, Kepware and all other popular integrated software platforms

- Native support for Azure, AWS, and Google Cloud via MQTT

- Real time system and performance monitoring of each machine

- Insight into operational performance bottlenecks

- Automatic archiving and classification of reject images

- Optional archiving of all inspection images

Reject Management Package

Reject Management Package include secure options:

- Lockable reject bin to ensure authorized access to rejected packages

- Sensors to ensure positive confirmation on expected rejects -Sensors to alert on “bin full” condition

- Air pressure sensor to alert for any out-of-range air supply problems

- Optional software-controlled lock for user configurable access

Filler Valve Monitoring

The addition of the filler valve monitoring package can extend capabilities to track the performance of each valve in the filler and report out detailed statistics on its performance and help plan maintenance and downtime. The package supports both beverage and food fillers

Full Range of Ejection Options

Peco InspX designs and manufactures a wide range of high performance ejectors and diverters to include single solonoid, multiple solonoid, swing arm, lift gate, drop gate, air blast, flexible rail, guided path, and heavy duty options

Simultaneous Underfill and Overfill Monitoring

With the addition of a Peco InspX FillTrac, the system can simultaneously measure underfill and overfill levels

Cocked/Missing Cap Detection

The cocked/missing cap sensor for plastic closures is an inexpensive way to ensure that containers are properly capped

Track and Trace Capabilities

In collaboration with industry-leading industrial package printers, Peco InspX offers an end-to-end package tracing system that prints on the inspected container the status (good or bad) of every package to ensure packages are auditable to their inspection results and X-ray image

RFID Access Control

Support automatic system authentication using customer ID badges. Supports a wide range of standard access protocol frequencies

Sanitary Design

Can be equipped with an IP69K enclosure for high pressure wash down environments

Remote Operator Console

The remote operator console provides complete system monitoring and control up to 6 meters from the system inspection assembly

Missing Foil Detection

The missing foil sensor verifies the presence of foil seals under caps