This blog post will cover finding bone contaminants using X-ray inspection. Two common types of X-ray inspections for finding bone is can inspection and raw product inspection.

- Can Inspection

The most specific example when you think about bone in product is bone ending up in tuna fish cans. That’s a very challenging application because tuna bones are extremely small and thin, and they’re in a very high-density metal container.

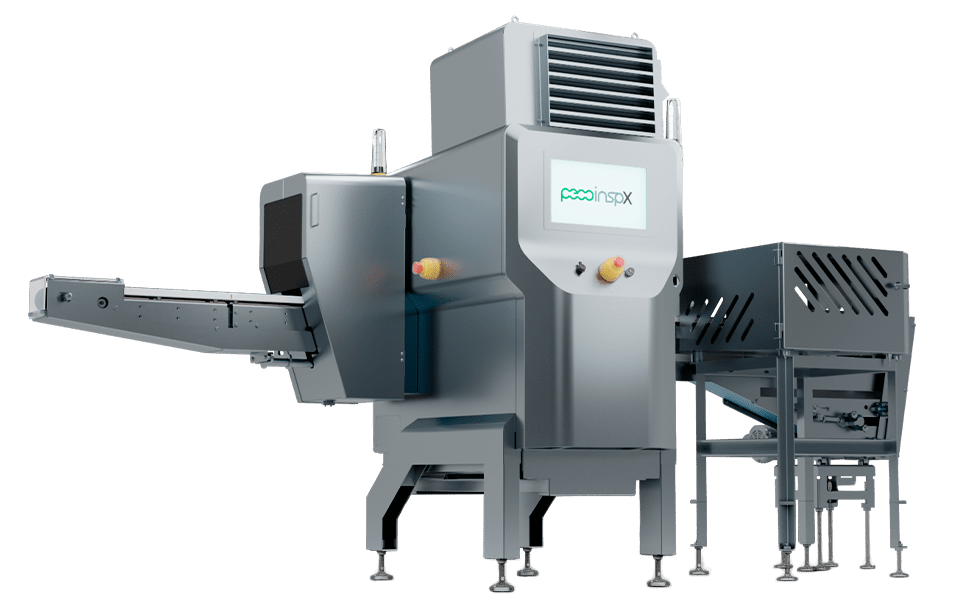

In order to find something that is low-density in a can, you need a lot of signal-to-noise ratio. That means you need an X-ray system that’s capable of finding very-low-density things in a very hard environment. Peco InspX has the most high-contrast X-ray tube on the market: the 600-watt beryllium window tube. Combining that with our side-view system ins perfect for this application.

You’ll need a good detector for this: something that can detect very subtle variations in density. And because bones are asymmetric, we often recommend customers have multi-beam systems for these kinds of can applications.

Think about how thin and small a fishbone is. Now imagine that you’re looking at a fishbone head-on – that it’s pointing directly at your face. It seems even smaller, then. That would be very hard to detect with a single-beam system. Now think about looking at a fishbone from the side. While still quite small, it’s easier to see. That’s why a multi-beam X-ray system is a better bet for bone detection: it looks at bones from the side. The multi-beam system means you’ll get several images of that geometry and you’ll increase your probability of detection by 60%.

So for very high-speed bone applications, we can find something like a 3-millimeter long bone in a single tuna fish can. That’s robust detection!

- Raw Product Inspection

An example of this would be a chicken breast in a very simple plastic container. That has different types of challenges than the can inspection; this has a broader application (it’s not only chicken – think beef or fish or pork, as well). We can find bones in raw products as well as we can find them in cans.

Let’s consider a raw chicken breast. Using a high-resolution imaging system, you might be able to see two chicken bone fragments in it. When animals expire, their bones leech calcium, and that calcium is the easiest thing for the X-ray system to find. However, it’s also possible to find the bones themselves.

Finding bones in a chicken breast gets down to the same things discussed in can inspection. You want extremely high signal-to-noise ratio, so you can single out the bone from the product itself. You also need good software that’s able to find the entire bone and make sure it’s not only easy to detect but also so you can save as much product as possible.

When Peco InspX systems create the high-resolution images, we have a separate light table that will highlight where the bones are. Then, you can cut them out, and run the now bone-free product back through the machine – rather than having to throw the entire product away.

For fish bones, which are even smaller, our ultra-high-resolution 0.48-millimeter system can find them in any kind of fish product.

- What Your Vendor Should Provide

So if you’re doing bone detection, it’s important you understand what your vendor provides in terms of imaging resolution and the kind of X-ray tube that they’re using.

Raw product inspection goes great with our beryllium window tube. (With cans, it’s a little harder to take advantage of the beryllium for technical reasons.) You can see cartilage and tendons and other types of denser protein product. If you want to remove those, you can do so.

When you want to learn about protein and bone inspection, visit the Peco InspX website. You can also click on the link below.

If you want more helpful resources from Peco InspX visit https://www.peco-inspx.com/lp/resources