Is there anything else inside your product?

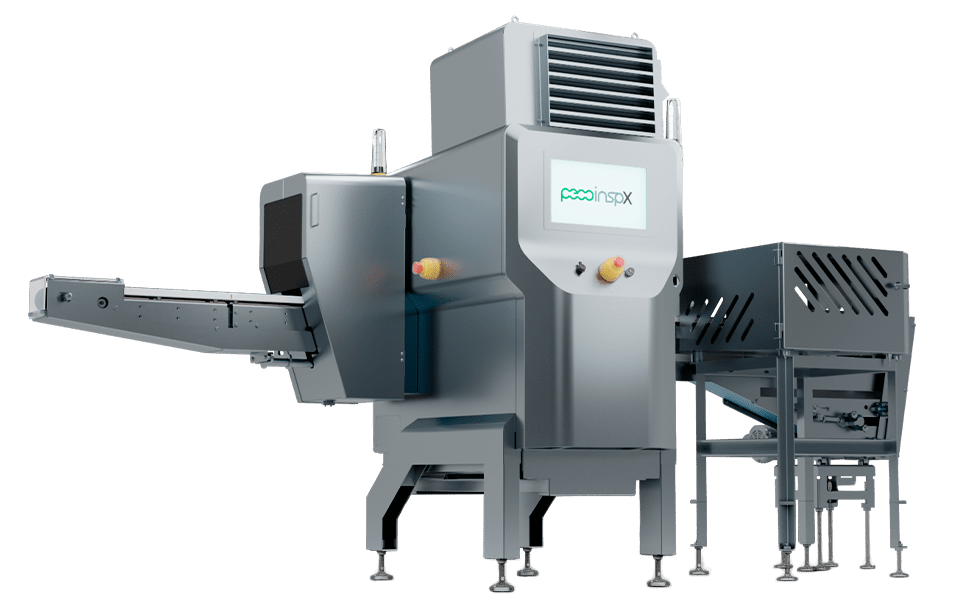

Introducing Our Newest X-Ray Inspection System

Seamtrac Legato

360° Can Seam Analyzer

The first inline, 360-degree, non-contact seam inspection system. SeamTrac Legato sets a new standard in canning quality control with real-time defect detection, advanced seamer monitoring, and precise headspace control.

Multiple X-ray inspection beams with overlapping coverage enables the Legato to inspect within multi-layered seams to identify a range of defects.

Applications

Peco InspX manufactures innovative and reliable inspection systems leveraging the latest in technology and software algorithms. Our products are solution driven for all industries, package types and contaminants.

Across a range of product and package considerations, X-ray inspection is the most effective, efficient and reliable means of ensuring your product has not been compromised.

Peco InspX’ 60 years in package inspection has built on strength after strength. Cutting edge X-ray inspection solutions combined with a rich package inspection catalogue have established Peco InspX’ place at the forefront of the inspection industry.

Peco InspX is a leading provider of inspection systems for the food, beverage, and life science industries. Headquartered in Silicon Valley, California, we combine cutting edge technology with rugged construction to produce high performance, reliable inspection equipment. From X-ray inspection to fill level detection, Peco InspX equipment addresses a broad range of inspection applications.

Products

X-ray systems

Fill level monitors

Other solutions