Disrupted global supply chains during the pandemic focused acute attention on food and beverage manufacturing and critical shortages they faced. Metal containers became more difficult to source, and came at an increase cost. Making every container count drives profitability – X-ray ensures only quality product makes it to customers.

Can Prices Continue to Soar

Growing demand and finite can production means every can has to make it to market. Lighter weight canstock has advantages and disadvantages: Pro – Improved Transportation Costs; Con – Higher Risk of Damage

Quality Matters

Outbound product must be high quality, filled accurately, and delivered in a solid, well-sealed container

Discarded Cans = Higher Costs

X-Ray Delivers Results

Full Container X-ray reduces waste and optimizes OEE by comprehensively:

- Monitoring Volumetric Fill Levels

- Finding Foreign Material Including Metal

- Identifying Can Defects – Flawed Seams, Lids, Seals, Linings, and Dents

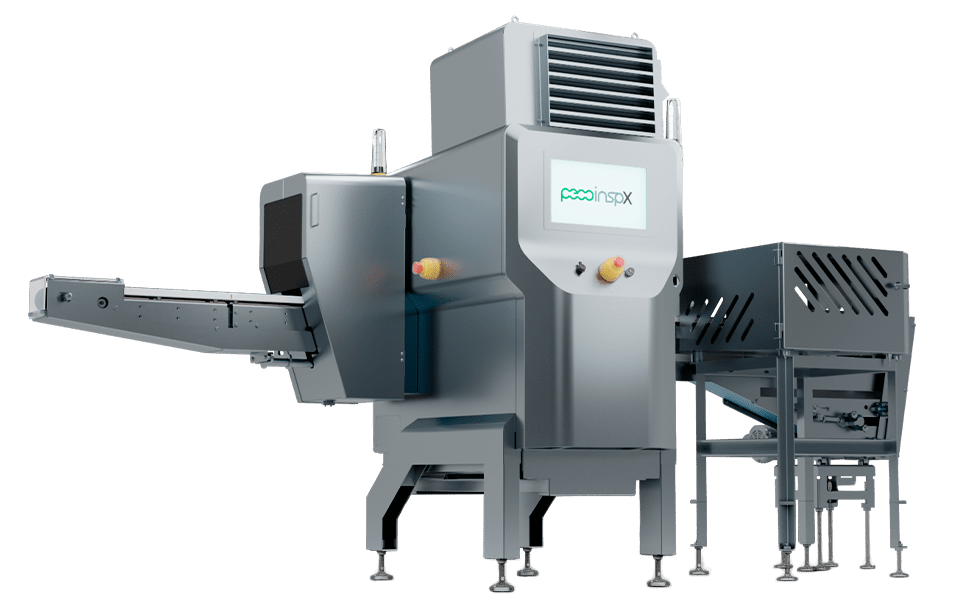

X-ray enhances your comprehensive quality program under highly automated conditions. Our solutions are safe, user friendly and HACCP Certified.

Integrating X-Ray Won’t Disrupt Your Lines

Implementing Peco InpsX non-contact inspection is straightforward – simply install over your existing lines. Inspections occur at the fasted filling speeds. Our one stop dashboard consolidates all operating measures to best manage holistic production measures.

Learn more about how Peco InspX can improve quality in your metal containers. Get in touch via the form on this page or give us a call at 800-732-6285. For additional information about Can Inspection – including finding metal in metal, please download our eBook.