Large containers can prove difficult to fully inspect. Read this blog to learn how X-ray inspection is superior to other forms of inspection for large container applications.

It is not widely known that inspection applications can be implemented for containers as large as five gallons. These large containers require an inspection configuration that is equipped to handle abnormal dimensions. The majority of inspection systems are not designed for inspecting containers in the five-gallon size range.

In some cases metal detectors are used to inspect these large containers, however, this method has limited capabilities as to what type and size of foreign contaminants it is actually able to detect.

Firstly, a metal detecting inspection system will only be able to detect metal contaminants. This leaves all other possible contaminants undetectable, including glass, stones, and plastics.

Secondly, most metal detecting inspection systems are only capable of finding metal contaminants with at least one dimension larger than five to six millimeters. Anything smaller than that will likely fail to detect and have the potential to cause damage to a companies reputation if the contaminant were to be discovered by a consumer.

In order to provide production with a more complete foreign contaminant inspection, it is recommended to use an X-ray inspection system. Not only can an X-ray inspection system detect many different types of contaminants it is also capable of detecting much smaller contaminants than other inspection solutions.

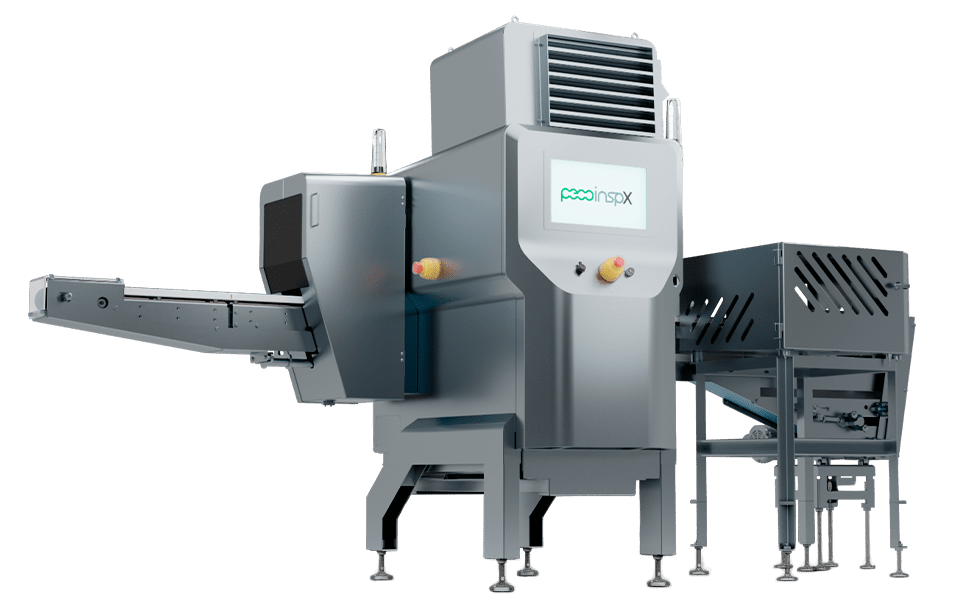

A pail inspection system from Peco InspX is capable of detecting contaminants as small as two millimeters, and glass contaminants as small as five millimeters in a five-gallon container.

If you have questions about your large container inspection needs, contact Peco InspX today.

If you want more helpful resources from Peco InspX visit https://www.peco-inspx.com/lp/resources